18 min read

Supplier Risk Management Best Practices: 6 Steps to Safeguard Your Business from Supply Chain Disruptions

Introduction: How Semantic Visions Transforms Supplier Risk Management

Managing supplier risks is not just about avoiding disruptions—it’s about gaining a competitive advantage. In my experience, the companies that thrive are those that leverage real-time intelligence to anticipate, assess, and mitigate supplier risks before they may escalate. That’s exactly what Semantic Visions’ Supplier Risk Management solution enables businesses to do.

Global supply chains are more complex than ever, and traditional risk management approaches are no longer sufficient. Semantic Visions’ AI-driven analytics and multi-tier supply chain mapping provide unparalleled visibility into supplier networks, helping businesses detect risks such as financial instability, geopolitical issues, cyber threats, and supply disruptions in real time.

Here’s why our clients rely on Semantic Visions for supplier risk management:

- Real-Time Risk Monitoring – Tracks emerging threats across global news, regulatory updates, and financial data.

- Multi-Tier Supply Chain Mapping – Identifies vulnerabilities deep within supply chains to mitigate single points of failure.

- Predictive Analytics – Uses AI to forecast disruptions and provide early warnings before risks materialize.

- Adverse Media Monitoring – Flags negative supplier coverage to prevent reputational and compliance risks.

By integrating Semantic Visions into your risk management strategy, you’re not just reacting to disruptions—you’re staying ahead of them. Let’s dive into the best practices and tools that make supplier risk management a powerful asset for resilient and successful businesses.

Key Takeaways

Before diving into the details, here’s what you’ll learn from this article

- Why supplier risk management is essential and how it impacts business continuity and profitability.

- How to identify supplier risks using advanced tools and real-time monitoring.

- 6 Best practices for mitigating supplier risks, including diversification and AI-driven analytics.

- How Semantic Visions enhances supplier risk management with AI-powered monitoring, predictive analytics, multi-tier supply chain mapping, and Adverse Media Monitoring

- Real-world examples of supplier risk scenarios to help visualize how disruptions, such as cyber attacks or quality issues, unfold in practice.

Why Supplier Risk Management Matters: Lessons from Real-World Challenges

From my experience, supplier risk management is not just a theoretical concern—it’s something that directly impacts operations, profitability, and reputation. Over the years, I’ve seen businesses struggle when they don’t have the right systems in place.

Here’s what I’ve learned firsthand about why this matters:

- Unforeseen Financial Collapses: I once worked with a company that sourced critical components from a supplier that suddenly declared bankruptcy. Without prior warning, their production came to a halt. Semantic Visions’ financial risk tracking would have flagged early warning signs, allowing them to find alternative suppliers in advance.

- Geopolitical Disruptions: Another case involved a business dependent on a supplier in a politically unstable region. When trade restrictions hit, they had no backup plan. Using Semantic Visions’ geopolitical risk monitoring, businesses can identify high-risk regions and diversify suppliers before disruptions happen.

- Adverse Media Fallout: A global retailer I advised had no visibility into a supplier’s unethical labor practices until negative media coverage surfaced. Semantic Visions’ adverse media monitoring provides early warning signals, allowing companies to make informed decisions before reputational damage occurs.

- Hidden Supply Chain Weaknesses: Many businesses only look at their immediate suppliers, ignoring deeper-tier risks. I’ve seen organizations get blindsided when a second-tier supplier had a cybersecurity breach, halting their operations. Multi-Tier Supply Chain Mapping by Semantic Visions would have uncovered this vulnerability in advance.

What I’ve learned through these experiences is that supplier risk isn’t just an abstract problem—it’s a constant threat to operational stability. Companies that actively monitor their suppliers with real-time data, predictive analytics, and risk intelligence tools provided by data experts like Semantic Visions are the ones that stay resilient in the face of uncertainty.

By implementing these lessons, businesses can safeguard their supply chains and avoid becoming another cautionary tale in an increasingly volatile global market.

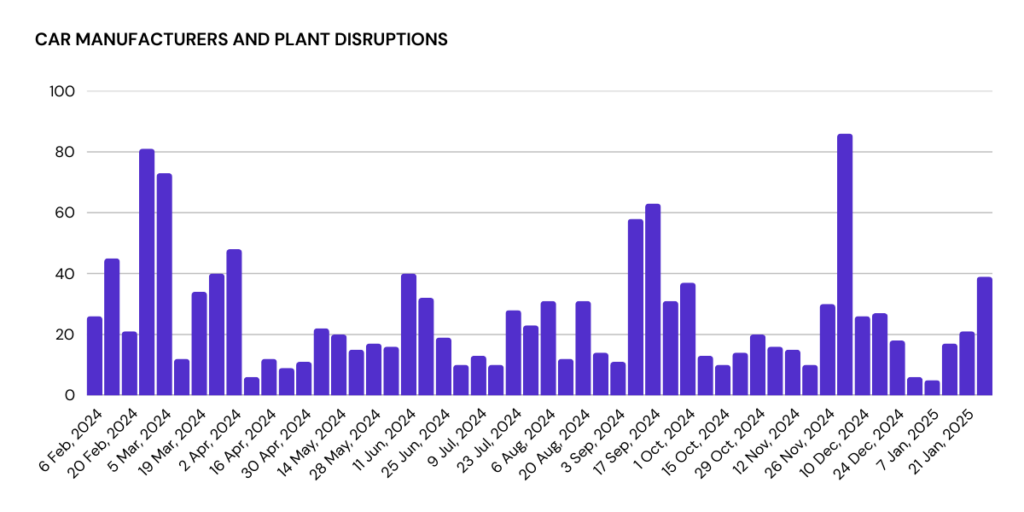

Common Supplier Risk Examples:1. Financial Instability Leading to Supplier Insolvency A supplier experiencing financial distress may suddenly declare bankruptcy, leaving businesses scrambling for alternatives. AI-powered financial risk monitoring can detect declining credit ratings, delayed payments, and liquidity concerns early on. 2. Regulatory and Compliance Violations A supplier failing to meet industry regulations or facing legal actions can disrupt business operations and damage brand reputation. AI-driven adverse media monitoring scans global news and regulatory databases to flag potential compliance issues before they escalate. 3. Geopolitical and Trade Sanctions A sudden trade embargo or new tariffs on a supplier’s country can cause unexpected delays or cost increases. AI-based geopolitical risk tracking helps companies anticipate these risks by monitoring international relations and policy changes. 4. Cybersecurity Breaches and Data Leaks Suppliers handling sensitive data are attractive targets for cybercriminals. A security breach can expose confidential business information or disrupt supply chain operations. AI-powered cyber risk assessments analyze threat intelligence sources to identify suppliers vulnerable to cyber threats. 5. Environmental and Climate-Related Disruptions Natural disasters, such as floods or wildfires, can halt supplier production and impact logistics. AI-enhanced climate risk modeling evaluates environmental data to predict and mitigate supply chain disruptions caused by extreme weather events. |

How to Identify Supplier Risks: Key Methods and Tools

Identifying supplier risks is the first fundamental step in managing them effectively. Without a clear understanding of the potential threats within your supply chain, it’s impossible to develop strategies to mitigate or avoid them. Here, we’ll explore some of the most effective methods for identifying risks in your supplier network.

Supplier Financial Health Assessment

One of the most critical risk factors is the financial stability of your suppliers. A supplier in poor financial health may be unable to fulfill orders on time or might go out of business entirely, causing disruptions to your supply chain. Tools such as credit reports and financial analysis can help assess the financial health of your suppliers. Companies like Dun & Bradstreet offer valuable insights into a supplier’s financial standing, enabling you to make informed decisions.

Geopolitical Risks and Natural Disasters Alerts

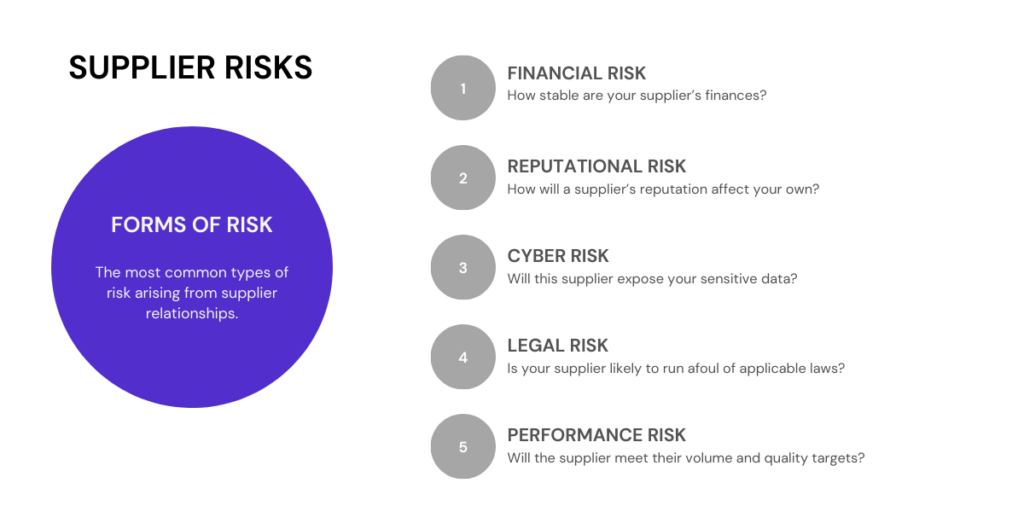

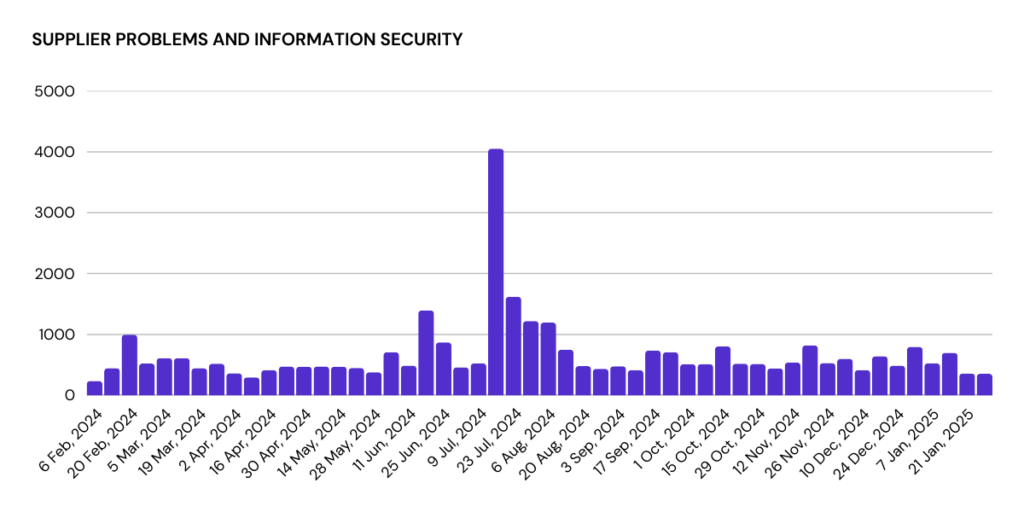

Geopolitical instability and natural disasters have a significant impact on supply chains. Suppliers located in regions prone to political unrest, economic instability, or environmental hazards are at a higher risk of disruption. For instance, The Economist regularly publishes reports on geopolitical events that could impact global supply chains, helping businesses stay informed about potential risks in specific regions. Also, Semantic Visions’ monitoring tool regularly provides real-time updates on global events such as natural disasters, see below.

Supply Chain Mapping Tools

One of the most effective ways to identify risks within a multi-tiered supply chain is through supply chain mapping. By visualizing your entire supply chain, from raw material suppliers to end customers, you can identify weak links or areas that are particularly vulnerable to disruption. Solutions like Semantic Visions’ Multi-Tier Supply Chain Mapping provide businesses with the tool to identify risks that may propagate throughout the chain, offering a clearer understanding of potential threats at every level.

Supplier Audits and Performance Reviews

Regular audits and performance reviews are key to uncovering any issues that may not be immediately visible. By reviewing a supplier’s past performance, including on-time delivery rates, product quality, and compliance with industry standards, you can identify patterns that could signal a future risk. Websites like Supply Chain Quarterly provide best practices for conducting thorough supplier audits and improving supplier performance monitoring.

Use of Artificial Intelligence and Predictive Analytics

Artificial intelligence (AI) and predictive analytics are becoming increasingly valuable in identifying potential risks within supply chains. Automatic analysis of vast amounts of data from a variety of sources, such as social media, news outlets, and market trends, helps to predict disruptions before they occur. Leading AI companies like IBM Watson are providing businesses with powerful tools to anticipate supply chain risks using advanced data analysis.

To better illustrate how supplier risks manifest in real-world scenarios, here are some of the most common risks businesses face and how AI-driven tools can help mitigate them:

How AI Enhances Supplier Risk Management:Early Warning Signals – AI algorithms analyze news sentiment and financial indicators to detect subtle shifts that could signal supplier instability. Geopolitical and Economic Forecasting – AI models evaluate macroeconomic trends and policy changes that may affect suppliers operating in volatile regions. Automated Anomaly Detection – AI-driven systems identify irregularities in supplier behavior, such as delays in production or unexpected price fluctuations. Risk Scoring and Prioritization – By assessing risk factors holistically, AI assigns risk scores to suppliers, helping businesses prioritize their risk mitigation efforts. Scenario Planning and Simulations – Predictive analytics enable companies to model different risk scenarios and develop contingency plans accordingly. |

By integrating AI-driven risk intelligence, businesses can proactively manage supplier risks instead of reacting to crises when it’s too late. Semantic Visions’ predictive analytics and real-time monitoring solutions equip businesses with the insights they need to navigate today’s unpredictable supply chain landscape with confidence.

How to Manage Supplier Risks: Strategies for Mitigation and Prevention

Once supplier risks have been identified, it’s crucial to implement strategies to manage and mitigate them. Effective risk management helps businesses stay resilient in the face of disruptions and ensures that the supply chain continues to operate smoothly. In this section, we’ll explore what strategies for managing supplier risks businesses employ.

- Diversification of Suppliers

- Collaborative Relationships with Suppliers

- Developing Contingency Plans

- Monitoring and Tracking with Technology

- Contractual Agreements and Risk Sharing

- Regular Supplier Audits and Performance Reviews

1/ Diversification of Suppliers

One of the most effective ways to manage supplier risk is to diversify your supplier base. Relying on a single supplier for critical components can leave your business vulnerable if that supplier experiences disruptions. By working with multiple suppliers in different geographic regions, you can spread your risk and avoid significant disruptions in case one supplier faces issues. For example, McKinsey & Company offers research on the benefits of diversifying suppliers to increase supply chain resilience.

2/ Collaborative Relationships with Suppliers

Building strong, collaborative relationships with key suppliers is essential for risk management. By fostering transparency and open communication, businesses can address potential issues before they escalate into larger problems. Regular meetings and continuous discussions about risks help both parties stay aligned. Semantic Visions collaborates with SAP Ariba to provide enhanced tools for supplier risk management. Together, they offer businesses a comprehensive approach to monitor supplier performance and risks in real time.

Additionally, as highlighted in this article on ADM, adverse media monitoring plays a crucial role in compliance and risk management. By leveraging media monitoring tools, businesses can stay informed about negative news or risks surrounding their suppliers, helping them proactively address potential issues that may impact the supply chain.

3/ Developing Contingency Plans

Having contingency plans in place is crucial for managing unforeseen disruptions. These plans should outline specific actions to take in case of disruptions, such as natural disasters, supply shortages, or supplier insolvency. A good contingency plan ensures that businesses can respond quickly and minimize the impact of disruptions. Resources like BCP Builder provide guidelines for creating robust business continuity plans that can be adapted for supply chain management.

4/ Monitoring and Tracking with Technology

Incorporating technology into your risk management strategy allows for real-time monitoring of your supply chain, making it easier to identify and respond to risks as they arise. Tools like Semantic Visions’ Multi-Tier Supply Chain Mapping offer advanced features for monitoring supplier performance and supply chain activity. By continuously tracking supply chain operations, you can stay ahead of potential disruptions and take immediate action when necessary.

5/ Contractual Agreements and Risk Sharing

Establishing clear terms in contracts with suppliers is essential for managing risks. These contracts should include clauses that specify how risks will be shared and what actions will be taken if issues arise. Risk-sharing agreements can protect both parties and ensure that there is a plan in place for addressing any disruptions. Resources like the International Trade Administration provide detailed guides on crafting contracts that protect both businesses and suppliers from risk.

6/ Regular Supplier Audits and Performance Reviews

Ongoing audits and performance reviews help ensure that suppliers continue to meet agreed-upon standards and expectations. By regularly assessing supplier performance, you can identify potential problems early and take corrective action before they become significant risks. Websites like Supply Chain Dive offer articles and reports on best practices for supplier audits, helping businesses optimize their supplier relationships.

Leveraging Technology for Greater Resilience: Semantic Visions’ Tools for Supplier Risk Management

The rise of digital technologies has revolutionized how businesses approach supplier risk management. Today, organizations have access to a range of advanced tools that can help identify, monitor, and mitigate risks in real-time. In this section, we will explore some of the most effective tools available for managing supplier risks.

Multi-Tier Supply Chain Mapping

One of the most powerful tools for managing supplier risk is multi-tier supply chain mapping. This approach allows businesses to visualize the entire supply chain, identifying risks at various levels and gaining a comprehensive understanding of supplier relationships. Tools like Semantic Visions’ Multi-Tier Supply Chain Mapping enable businesses to track and analyze their supply chain activity, providing actionable insights into potential risks and disruptions before they impact operations.

By mapping out every tier of the supply chain, businesses can identify single points of failure and potential vulnerabilities, allowing them to take preventive actions. This level of visibility is crucial for proactively managing risks in an increasingly complex and interconnected global supply chain.

Example of Multi-Tier Supply Chain Mapping:

Artificial Intelligence and Predictive Analytics

Artificial intelligence (AI) and predictive analytics are transforming ways how businesses forecast and manage supplier risks. These technologies analyze large volumes of data from various sources, such as news, social media, financial reports, and more, to predict potential disruptions. By utilizing AI-driven tools, businesses can stay ahead of emerging risks and make more informed decisions.

Leveraging AI to predict supply chain disruptions provides companies with early warnings of potential risks. By integrating AI and predictive analytics into your supplier risk management strategy, you can anticipate issues before they occur and respond more effectively to mitigate their impact.

Adverse Media Monitoring

Monitoring adverse media is an essential component of effective supplier risk management. Negative news coverage, such as financial scandals, regulatory issues, or environmental violations, can be a sign of underlying risks that may affect a supplier’s ability to meet its commitments. By using tools that monitor global news and media outlets, businesses can stay informed about developments impacting their suppliers.

Semantic Visions, in collaboration with SAP Ariba, helps businesses leverage adverse media monitoring to stay ahead of supplier risks. As highlighted in this SAP blog post, employing such monitoring tools allows businesses to gain deeper insights into the reputational risks and compliance challenges associated with their suppliers.

Why is Supplier Risk Management important from our own experience?Semantic Visions realizes the importance of Supplier risk management in today’s fast-paced business environment, where even minor disruptions can lead to significant delays, financial risks, or revenue loss. Factors like economic downturns in key supplier regions or sudden financial instability in a supplier can ripple through operations.These challenges can be addressed by providing businesses with real-time insights into supply chain operations. Such advanced technology enables our clients to dynamically track their supply chains, manage third party risk, monitor selected companies, and identify potential risks before they escalate.By integrating Semantic Visions’ solutions into their Supplier Risk Management strategies, businesses can enhance visibility and predict disruptions with greater accuracy, enhancing their operational resilience. These customized tools empower organizations to take proactive actions to prevent or minimize the impact of supply chain threats, ensuring smoother operations and a stronger competitive edge in an unpredictable market. |

Case Studies: Real-World Examples of Supplier Risk Management Success

Understanding the theory behind Supplier Risk Management is fundamental, but seeing how these strategies are applied in the real world can provide valuable insights. Many companies have successfully implemented supplier risk management solutions to mitigate disruptions and strengthen their supply chains. These real-world examples not only highlight the importance of having a proactive risk management strategy in place but also demonstrate how modern tools can enhance decision-making and improve overall supply chain resilience.

Leveraging Supply Chain Mapping for Resilience

Take, for instance, a large manufacturing company that faced frequent disruptions in its supply chain due to natural disasters in the regions where its suppliers were located. By leveraging advanced technologies like Semantic Visions’ Multi-Tier Supply Chain Mapping, the company was able to visualize its entire supply chain and identify areas of vulnerability. This visibility allowed them to diversify their supplier base and establish alternative sourcing options for critical materials. As a result, the manufacturer was able to maintain continuity during a major supply chain disruption caused by a natural disaster, while also reducing the overall risk exposure in the long run.

Monitoring Financial Stability to Prevent Disruptions

Similarly, another example comes from a global retailer that was struggling to manage the risks associated with their suppliers’ financial health. By utilizing advanced tools such as supplier performance management systems and integrating them with predictive analytics, the retailer was able to monitor supplier stability in real time. When one of their key suppliers showed signs of financial distress, the retailer had the foresight to switch to alternative suppliers, avoiding a potential disruption in product availability. This proactive approach not only helped them avoid stock shortages but also strengthened their relationship with more reliable suppliers, enhancing the overall performance of their supply chain.

Using Adverse Media Monitoring for Reputation Management

Moreover, as companies increasingly recognize the importance of compliance and reputational risks, many are turning to adverse media monitoring as a vital tool. For instance, a leading electronics company integrated adverse media monitoring into their supplier risk management strategy to stay ahead of any potential reputational risks. Through tools that monitor news and social media, they were able to identify negative media coverage surrounding one of their suppliers, related to an environmental regulations violation. With this timely information, the company was able to make an informed decision to sever ties with the supplier before any significant reputational damage occurred.

Conclusion:

In today’s unpredictable global market, supplier risk management is not just a necessity—it’s a strategic advantage. Companies that actively monitor and mitigate supplier risks are better positioned to maintain operational stability, protect their reputation, and ensure long-term success. Leveraging AI-driven analytics, adverse media monitoring, real-time monitoring, supply chain mapping, and adverse media monitoring helps businesses anticipate disruptions before they escalate.

Recommendations:

- Proactive risk management minimizes supply chain disruptions and financial losses.

- AI-powered monitoring and predictive analytics provide early warnings on supplier instability.

- Multi-tier supply chain mapping enhances visibility into hidden vulnerabilities.

- Financial risk tracking prevents reliance on unstable suppliers.

- Adverse media monitoring safeguards brand reputation and compliance.

- Collaboration with trusted partners like Semantic Visions strengthens risk mitigation.

Next Steps:

To future-proof your supply chain, start by integrating Semantic Visions’ Multi-Tier Supply Chain Mapping and AI-driven risk intelligence into your supplier management strategy. By doing so, you’ll gain real-time insights, proactively address risks, and build a more resilient and agile supply chain for long-term success.

_______________________________________________________

Frequently Asked Questions (FAQs)

1. What is Supplier Risk Management?

Supplier Risk Management involves identifying, assessing, and mitigating potential risks that could disrupt the supply chain. These risks can stem from financial instability, geopolitical factors, natural disasters, regulatory changes, or issues related to the supplier’s performance. A comprehensive risk management strategy helps businesses ensure continuity, reduce disruptions, and protect their reputation.

2. Why is it important to monitor supplier financial health?

Monitoring supplier financial health is crucial because financial instability can lead to delays, quality issues, or even supplier insolvency, all of which can disrupt your supply chain. Tools like financial reports, credit assessments, and performance management systems help businesses assess the stability of their suppliers and take proactive measures to avoid supply chain interruptions.

3. How can multi-tier supply chain mapping help mitigate supplier risks?

Multi-tier supply chain mapping allows businesses to visualize their entire supply chain, including all levels of suppliers. This comprehensive view helps identify vulnerabilities and dependencies within the supply chain, enabling companies to diversify suppliers, create backup plans, and anticipate potential disruptions. By mapping your supply chain, you gain greater visibility and can act swiftly to manage risks at every level.

4. What role does adverse media monitoring play in supplier risk management?

Adverse media monitoring helps businesses stay informed about potential risks related to their suppliers by tracking news, social media, and public reports. Negative media coverage, such as scandals or compliance violations, can indicate underlying issues that may affect supplier reliability and reputation. By monitoring such media sources, businesses can identify risks early and take informed actions to mitigate them.

5. How can Semantic Visions’ Multi-Tier Supply Chain Mapping help my business?

Semantic Visions’ Multi-Tier Supply Chain Mapping provides real-time insights into your supply chain, allowing you to monitor and track risks across multiple tiers of suppliers. This tool helps you identify vulnerabilities, improve supplier relationships, and ensure business continuity by providing the necessary data to manage and mitigate risks effectively.